PAYPER receives ISO 9001 certification for quality management

Quality and customers come first

We are pleased to announce that PAYPER has been certified to the internationally recognized ISO 9001:2015. The certification for PAYPER's quality management system was awarded on March 7, 2024, and issued through Bureau Veritas, a leading global certification entity.

PAYPER’s certification covers a broad range of our operations, from engineering to sales, R+D, purchase, manufacturing, warehouse management, commissioning and services such as customer support and spare parts management. So, it covers all internal processes of our organization including the interactions with our suppliers and customers.

The rigorous criteria of the certification ensure ongoing analysis and improvement of product quality so that our solutions for bagging, palletizing and wrapping are even more aligned with customers’ needs.

“Acquiring ISO 9001 accreditation validates our ongoing commitment to high standards of quality and excellence in all aspects of our business. Moreover, the certification process has been an opportunity to identify areas for improvement and ultimately strengthen our business.”

Josep Mª Godia, Managing Director at PAYPER.

At PAYPER, we are proud to reach this important milestone and remain dedicated to upholding our commitment to excellence for our valued customers.

What is ISO 9001?

ISO 9001 is a globally recognized certification standard that defines the requirements for establishing a Quality Management System (QMS). It was developed and published by the International Organization for Standardization (ISO).

This certification provides a framework for organizations to define, implement, maintain, and continually improve their quality management processes and procedures.

The ISO 9001:2015 standard is based on numerous quality management principles, such as a robust emphasis on customer satisfaction, a process-oriented approach, active involvement from top management and an ongoing commitment to improvement.

Compliance with ISO 9001 demonstrates an organization's ability to consistently provide products and services that meet regulatory requirements and focus on customer satisfaction. Many organizations worldwide seek ISO 9001 certification to demonstrate their commitment to quality and improve their overall performance.

Related images

BAGGING OF FERTILIZERS

FERTILIZERS

The global demand for fertilizers is increasing, driven by a rapidly growing population. Meeting this demand requires an intensified approach to agricultural production, where fertilizers play an important role. However, the fertilizer industry's unique challenges demand careful consideration, especially when it comes to packaging. At PAYPER, we understand the complexities involved and offer specialized bagging equipment designed to address the corrosive and dusty nature of fertilizers.

One key challenge is the hygroscopic nature of fertilizers, whether in granulate or powder form. Managing moisture becomes crucial, adding an extra layer of complexity to packaging machinery and environmental conditions. Ensuring that the filled bag maintains its nominal weight and appearance throughout its entire lifecycle, from storage to transportation and delivery, is a priority for fertilizer manufacturers. When initiating a bagging and palletizing project, factors like preferred bagging technology, bag size and material, and total hourly output must be carefully considered, all while adhering to local and international regulations.

BAGGING AND PALLETIZING SOLUTIONS

For five decades, PAYPER has been present in the fertilizer sector, providing dosing and weighing systems, bagging machines, and palletizers. Our journey has been a collaborative one with our customers, resulting in the development of modern, robust, and user-friendly equipment tailored specifically for the fertilizer industry. At PAYPER, we specialize in solutions that adapt to each customer's unique needs.

Our commitment to excellence is evident in our anti-corrosion measures and dust emission controls incorporated into our bagging systems, addressing the challenges posed by corrosive and dusty fertilizers. Our installations are adaptable, offering reliable cleaning systems to prevent cross-contamination for clients handling various products. At PAYPER, we tirelessly explore and provide optimal solutions for every project.

Robust and user-friendly Bagging Solutions:

• Open Mouth Bagging machines – up to 1,800 bags/h

• FFS Bagging machines – up to 2,600 bags/h

• Valve Bagging machines – up to 2,000 bags/h

• Big-Bag filling machines – up to 100 Big bags/h

Matching Palletizing and Overpacking Systems

Choosing the right machinery for a complete fertilizer bagging line is of great importance. PAYPER ensures a seamless match, offering corresponding palletizers and overpacking systems with bags/hour rates tailored to each bagging system:

• Robotic palletizer

• Low-level infeed palletizers

• High-level infeed palletizers

• Stretch-wrapper or Stretch-hooder to maintain a stable pallet load and protect the bags from dust and humidity.

Related images

Our Best Wishes for Christmas and 2024!

We wish all our employees, partners and customers a Merry Christmas and a Happy New Year!

Related images

Enhanced and Expanded Open-Mouth Bagging Range

Enhanced and Expanded Open-Mouth Bagging Range

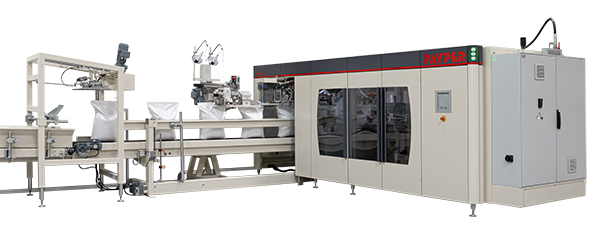

PAYPER is excited to unveil its upgraded and expanded open-mouth bagging range, featuring six fully automatic models capable of achieving high speeds of up to 1,800 bags per hour. Designed to accommodate a wide range of dry bulk materials, whether they are free-flowing or non-free-flowing, these machines are compatible with pre-made, open-mouth bags ranging from 5 to 25 kg. These bags can be constructed from various materials including paper, PE, PP, aluminium, or even a combination of PE and paper.

Our open-mouth bagging line, CSA, has undergone a comprehensive redesign and optimization process. This initiative has not only reduced energy consumption but also increased production speeds. In addition to these improvements, we are introducing a new patented bag presentation system, further expanding the capabilities of our range and enabling high-performance bagging at a rate of up to 1,800 bags per hour.

At PAYPER, we prioritize robust design, ensuring easy access for cleaning and maintenance, which in turn maximizes uptime for your operations. All our open-mouth baggers feature our advanced dosing and weighing systems. Our dynamic weight controller, MSX, is specifically tailored for the bag-filling process, allowing maximum weighing precision at high bagging speeds.

The versatility of our open-mouth bagger line means it can smoothly integrate into a wide array of industries, including mining, building, petrochemicals, chemicals, fertilizers, seeds, pet food and animal feed. We collaborate closely with our clients to tailor each project's configuration to their specific requirements, offering options for bag closure, bag deaeration, and handling corrosive, abrasive, or ATEX products.

With 50 years of experience in the market, PAYPER specializes in designing and manufacturing comprehensive, customized bagging lines. These projects encompass dosing, weighing, bagging, palletizing, and wrapping equipment. We are committed to delivering first-class solutions that meet your bagging needs.

Related images

A fresh drive for PAYPER Bagging India

A fresh drive for PAYPER Bagging India

The PAYPER India team has been visiting Interpack and PAYPER's international headquarters in Spain over the past few days. These meetings have strengthened PAYPER's dedication to offering the finest service possible to its clients throughout Asia.

PAYPER's Mumbai branch will play an important role in increasing our presence and image in India and Asia over the next few months. In addition to enhancing communication with our customers, our compromise is to reinforce commercial and technical support.

Curiously, Interpack fell on the 11th anniversary of the establishment of our Indian affiliate. Consequently, at the exhibition, in addition to exchanging impressions with our Asian colleagues, we also got the chance to commemorate the anniversary.

About PAYPER Bagging India

PAYPER established its subsidiary in India in 2012. Now, it consists of a manufacturing facility in Pune and sales offices in Mumbai. Fast and local service for our customers throughout Asia is ensured by these two locations and a team of more than 30 people.

Related images

PAYPER focuses on digitalization, accuracy and performance.

PAYPER focuses on digitalization, accuracy and performance.

Interpack, Düsseldorf, Germany. May 4-10, 2023 – PAYPER, one of the leaders in the bagging industry, is launching Pulsar, an all-in-one digital solution for advanced bagging management and service, at Interpack (Hall 12, Booth C06). MSX, the new weight controller, and the FFS bagger from the ASSAC series will also play a prominent role in the show.

PAYPER stands for accuracy, control and performance.

Accuracy.

Weighing has been at the centre of interest in PAYPER’s R&D&I department ever since the first weighing device was designed in 1973. In line with the ongoing commitment to weighing accuracy, PAYPER will present MSX: a new dynamic weight controller. It ensures maximum accuracy at high bagging speeds, being one of the most accurate weighing systems in the bagging industry. Accredited by official metrology institutions, it is specifically designed for the bagging of all types of solid products: granules, flakes and fine powders.

Control.

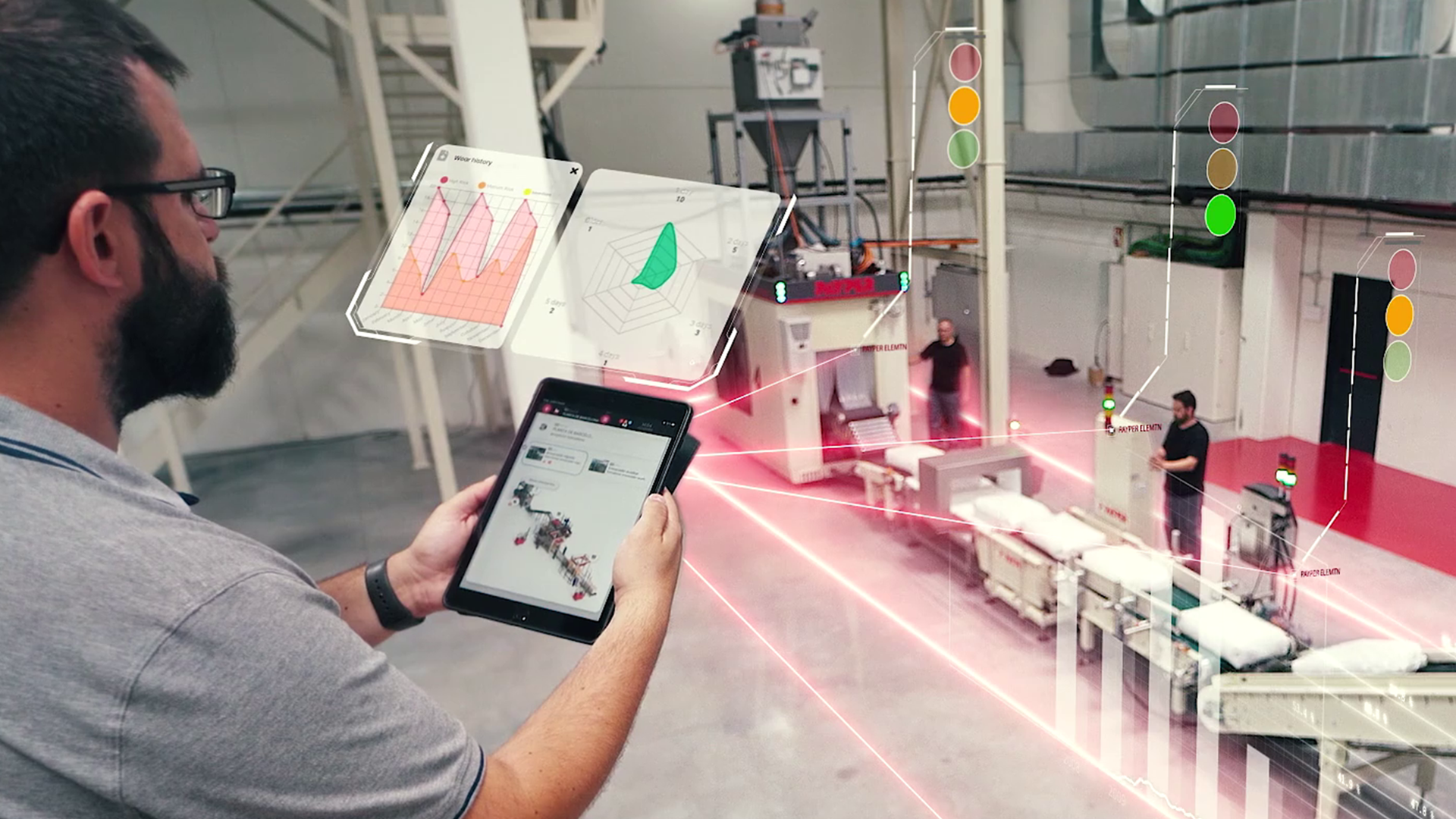

Pulsar ensures full control of the production processes with a single click. This new cloud-based software solution enables bulk good producers to digitalize their bagging lines taking their production to the next level.

At PACK EXPO International in Chicago in 2022 PAYPER introduced the Pulsar-S, to enhance customers’ after-sales-service experience. We are now introducing Pulsar M at the main meeting point for the packaging industry worldwide, Interpack 2023.

This all-in-one digital solution allows advanced management of production and service:

Pulsar S: Smart Customer Service and Maintenance.

Make the most of your production line with Pulsar S. The different modules allow plant managers, maintenance managers and operators to work together to increase the lifetime and effectiveness of the bagging line machinery. Among other actions, it is possible to perform:

- Predictive Maintenance: risk management, task scheduling and tutorials to reduce maintenance costs and machinery downtime.

- Quick spare parts management: orders, stock and deliveries.

- Easier Customer Service communication: Omnichannel support.

- Remote training and technical support: using augmented reality.

- Data-driven decisions: real-time KPIs and analytics.

Pulsar M: Future-proof production management

Pulsar M is a cloud-based software solution for the collection, visualization and analysis of data from complete bagging lines: from dosing to warehouse management. Among other functions, it is possible to access:

- Overall Equipment Efficiency (OEE) measurement.

- Alarm management: Step-by-step indications.

- Traceability: batch management.

- Monitoring: The status of every machine in the line can be monitored from any one of them.

Move towards Industry 4.0 with PAYPER!

Performance.

PAYPER designs and manufactures high-performance bagging lines for industry leaders: Turnkey projects including dosing, weighing, bagging, palletizing and overwrapping.

- Dosing and weighing: Wide range of dosing systems that adapt to the size, shape and fluidity of the product: gross or net weight, free-flowing or not, powdery, flakes or granulates.

- Bagging: High-performance automatic bagging machines for open-mouth bags, valve bags and FFS-tubular bags. Also, filling stations for Big Bag production lines.

- Palletizing: A wide range of robot and conventional palletizers for perfect pallet stability.

- Overwrapping: End-of-line solutions for ideal finishing and protection such as wrapping machines and stretch hood machines.

PAYPER will be showcasing an FFS bagging machine from the ASSAC series at the stand. This bagging system forms, fills and seals bags from a continuous tubular reel of plastic. An efficient solution for bagging all types of bulk solids applied in the food, petrochemical, fertilizer and building industries. The ASSAC FFS bagging machine stands out for its compact and heavy-duty design with easy access for cleaning and maintenance. Among the available options are: hygienic design for the food and chemical industries and an anti-corrosion configuration for handling corrosive and abrasive products. Do not miss the opportunity to see first-hand one of the fastest bagging machines on the market with performances of up to 2,600 bags/hour.

Find out more about PAYPER’s product range and the new digital solution, Pulsar, by booking a meeting in advance. Our specialists will be happy to welcome you at our stand C06 in Hall 12 at Interpack from May 4 to 10, 2023.

50th anniversary

PAYPER is celebrating an important milestone in its history in 2023, its 50th anniversary.

"We are very proud of what we have achieved since we designed our first weighing system for the fertilizer industry in 1973. Today, we are recognized worldwide as one of the market leaders in packaging for bulk solids. This has only been possible as a result of the close collaboration with our worldwide team, our long-term partners and our customers which has taken us to where we are today."

Josep Mª Godia, Managing Director at PAYPER.

Related images

360º Virtual Tour of PAYPER’s Global headquarters

Immerse yourself in a 360-degree virtual office tour of our Headquarters, based in Bell-lloc, near Barcelona (Spain). A look inside, where we take bagging automation of bulk solids to the next level.

How to move around. For a fully immersive experience exploring our building, you can either use the arrows on the ground or click directly on a particular area in the menu. Also, click the hotspots to learn more.

New state-of-the-art facilities. The new offices, fully operational since the end of 2021, have a fantastic combination of aesthetics, open space and comfort, allowing collaboration, interaction and teamwork like never before.

From ideas to reality. The office area measures 2,500 m2, distributed over three floors. Explore the different spaces, from the meeting rooms where ideas come to life, to the different areas where the employees work in collaboration. With a team of more than 150 highly qualified professionals, we accompany our customers throughout the entire process: from the creation of the initial layout to the close attention after the acquisition of the production line. More than 50 engineers form our Innovations and Projects team.

Manufacture of complete bagging lines. The location change allowed us to replace the two existing production centres and increase our efficiency and production rates by 50%. We currently have a total of 6,000 m2 dedicated to the production and 800 m2 to the new Product Testing Area. This space is exclusively dedicated to testing products, bags and processes for our customers and being an important area for the company's R+D+i.

Take PAYPER’s Virtual Office Tour now:

Contact us if you want to have an in-person tour of our new facilities and meet our team. You will see our manufacturing process in action, and we will show you how it all works.

Related images

PAYPER towards greater sustainability

Our new solar energy system is now operative. This modern photovoltaic plant has 218 panels. Together, they generate 99 kWp, which represents 50% of the energy consumed at our headquarters and factory located in Bell-lloc, near Barcelona (Spain). Each year we will generate 143,467 kWh, obtaining an approximate self-consumption of 13,553 kWh.

With this new commitment, we increase our utilization of clean renewable energy to protect the environment and our surroundings.

This project is just a part of the company's commitment to achieving the objectives towards sustainability in the coming years.

Related images

New Scara Robot Palletizer

PAYPER’s new Scara palletizing robot is the perfect tool for the automatization of your end-of-line process.

This fully automatic palletizing robot carries out all the necessary steps for your bags to form a nice, stable pallet.

The Scara operates in very little space, ideal for reduced footprints.

It can handle all sorts of bags of all sorts of material and it palletizes in different patterns with or without bag-overlapping.