Complete bagging and palletizing line for RAGT

When RAGT, a company dedicated to the production and research of seeds was planning the construction of a new plant in Northern Spain, the company relied once again on PAYPER as the supplier of the complete packaging line for the installation.

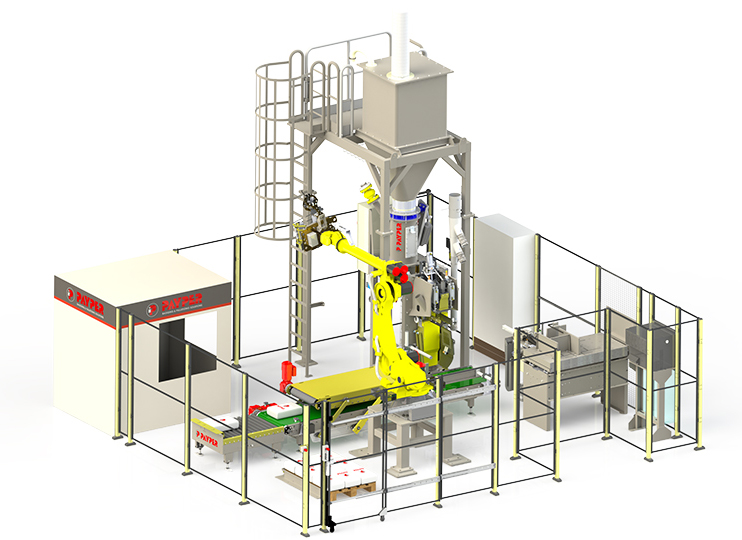

Engineers from the two companies worked out the best solution to meet all RAGT’s requirements for the new enterprise. The final solution consisted of a fully automatic open-mouth bagger, model CSA-95, with an easy change between bag sizes and a double labelling system.

In continuation of the bagging machine, a low-level infeed palletizer, model LLG-90, was installed. The special gripping head guarantees a perfect overlapping between the bags, ensuring a very stable and perfectly finished pallet. Additionally, RAGT required a Big-Bag filling station.

Both the pallets with bags as well as the Big-Bags are conducted towards the pallet wrapper, which assures a perfect finish and protection against humidity and dust of the bags containing seeds. In this particular case, we included a labelling system, able to stick labels on all 4 sides of the wrapped pallet.

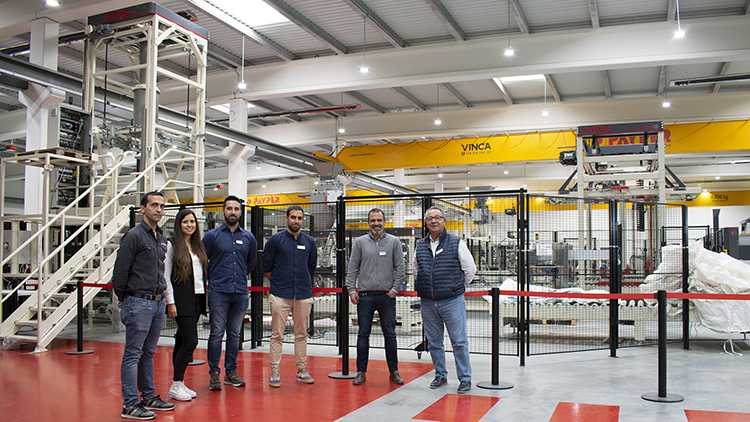

The complete line was fully tested in PAYPER’s installations before the FAT.

With the new Headquarters, situated 1 ½ hour from Barcelona, PAYPER has doubled the surface of production to some 10.000 m2.

“Our former factory had become too small and PAYPER has been looking forward to moving into our new premises”, says managing director, J.M. Godia. “It gives us the perfect setting for manufacturing and fully testing complete bagging and palletizing lines”.

Apart from the Cereals & Seeds industry, PAYPER has clients in many different sectors, such as the Chemical Industry, the Food Industry, the Animal Feed Industry, the Mineral Industry and Construction.

PAYPER exports to more than 70 countries, representing 85% of the turnover. The subsidiaries in France, Mexico, Brazil, India, the Middle East, Thailand, Russia and the Czech Republic assures local commercial and technical support.

Related images

Merry Christmas and a Prosperous New Year

In 2022, we will continue conducting Bagging and Palletizing projects with precision, experience, reliability and commitment.

The whole PAYPER team wishes you a wonderful holiday season and a prosperous New Year!

Related images

PAYPER in FIGAP 2021

From 5 to 7 of May, PAYPER’s Mexican Branch, TEPSA will be at FIGAP, Guadalajara Jalisco in Mexico.

We have taken all precautions to make it a safe and pleasant event for our guests as well as for our employees. It is with much illusion that we attend this exhibition and hope that many of our business contacts will come and visit our booth to discuss the newest developments within bagging and palletizing.

We look forward to seeing you at FIGAP, stand 406!

Related images

CAPACITY – PRECISION – RELIABILITY

New FFS Bagging System

We are happy to introduce the next member of the IMPULS-family: The ASSAC-U20.

The newest FFS bagging machine from PAYPER has been specially developed for the fast filling of bags with free flowing products, such as granules, plastic pellets and fertilizer prills. The U20 can fill an amazing 2,600 bags per hour without compromising on precision.

With almost 50 years of experience and close collaboration with the specific industries, PAYPER offers tailor-made solutions that fit each particular demand.

Here are some of the specific modular solutions for the ASSAC-range:

- Automatic roll film change – The production continues uninterruptedly while a new roll film is being prepared.

- ATEX-certification – The complete bagging solution is prepared for unstable environments.

- Anti-corrosion kit – The installation is optimized to be used with abrasive or corrosive products.

- Cleaning – Easy access to all parts of the installation. Different wet and dry cleaning systems are available to suit specific needs.

- Machine-status: Dual, visual indication of the status of the complete installation: OK /Warning / Error

- Corner sealing system – secures perfect, brick formed bags, ready for optimum palletization.

- Movable platform: The FFS bagger is fitted on a movable platform for easy transfer from one silo to another.

We work side by side with our client during the phases of design, commissioning and after-sales service. We are convinced that this close collaboration during all stages of a project is the best guarantee for an optimum and longlasting bagging solution.

Related images

Efficient Flour Bagging in Valve Bags

"The new bagging line produces more than we expected."

Hedwigsburger Okermühle GmbH in Germany is one of the oldest mills still in operation. It dates from 1318 and has had uninterrupted activity since 1820.

Okermühle contacted PAYPER through their German partner, SSB Wägetechnik GmbH, for a new valve bagging machine for wheat flour.

Together we designed their new line, which is a fully automatic installation consisting of an automatic bag presenter and a fluidization bagging machine. The flour is introduced by gravity into a chamber in which a stream of air from the bottom fluidizes the flour. Another flow of air from the top of the chamber conveys the product into the bag.

The fluidization system is the ideal technique for food products as it is very easy to clean, control and maintain. It facilitates a perfect cleaning of the whole bagging equipment in between different productions.

Once the bag is full, the valve is thermo-sealed by two ultrasonic bars. The result is a perfectly airtight bag with good protection against any external contamination. Thermo-sealing further minimizes dust emission.

Okermühle’s new bagging line fills and seals 180 bags per hour with one single filling nozzle. The project is designed to allow for a future expansion that will triple the production.

Birko Boeltzig, Okermühle's Sales and Project Manager, says:

“I would like to take this opportunity to thank the PAYPER/SSB team for a great job. The system works better than expected (233 bags/h unwelded). Our employees working with the bagging line look very happy and your commissioning engineers did a great job of training.

It was a good decision to work with you”.

Related images

DRACO - New Installations

In PAYPER, we are proud to be part of DRACO’s brand new installations in Muć.

This Croatian manufacturer of waterproofing products needed a bagging and palletizing solution for polymer-cement for the new factory.

PAYPER designed a custom-made solution and installed the compact ALL-IN-ONE which fills and palletizes the valve-bags in a fully automatic way with the need of only one operator. This installation featured ultrasonic valve sealing to protect the product and to avoid leakages. Just before palletizing, the bags pass through a bag flattener device to assure a stable and safe pallet.

DRACO’s Production Manager, Mr Ljubomir Bonković explains: “With the installation of PAYPER's ALL-IN-ONE solution, DRACO became a technological leader in the production of dry mortar materials in this part of Europe (Central Europe).” He adds: “Although the project was run during the COVID-19 crisis, it was completed on time, fully functional and within the budget. This was only possible to do due to the great commitment of the PAYPER-team.”

Watch DRACO’s video from the new installations.

Thank you for the words of praise and congratulations with the new installations. In PAYPER we can only be happy when our clients are pleased and satisfied with the solution we have provided. Good luck to the DRACO-team.

You can read more about PAYPER’s different solutions in the building sector in our dedicated catalogue here.

Related images

New IMPULS-design

It is with great enthusiasm that we present our new IMPULS-design for the future generation of bagging machines and palletizers.

On the outside we have given the machines a facelift: the new, streamlined look underlines the functional and modern technology that constitute the fundament of all our bagging and palletizing solutions.

On the inside, our designers have given the machines a general overhaul, attending to the details that will make the use, maintenance and after-sales service much easier.

One of the first bagging machines with the characteristic IMPULS-design is a fully equipped open-mouth automatic bagging solution. It features all PAYPERs solutions for modern, optimal and top-performing bagging of PET FOOD.

Read the story here

Watch the video here

Related images

PAYPER's New Headquarter

PAYPER’s new Headquarter – now finishing the last details. We look forward to moving into the new premises at the beginning of 2021.

See the full movie here

Related images

Unstable Pallets? We have the Solution!

PAYPER’s newly developed gripper head, SGR, builds an extremely stable and fine-looking pallet. The result is one of the best pallets made with a robotic palletizer.

The new gripper head with guide plates ensures that each bag is placed with great accuracy onto the pallet. It is even capable of doing layers of 3 or 4 bags.

Our palletizing robot is suited for both single and multi-line palletization and reaches a speed of up to 1.400 bags per hour.

This versatile robot carries out all the different palletizing functions: Picking and placing of bags, empty pallets and slip sheets and interlayer sheets.

Related images

Ready for Khimia in Moscow

Come visit us at the Khimia Fair in Moscow! PAYPER Russia CIS will be present together with our agent in Russia, SWEMA. You can find us in the Expocentre, booth 21A10 in hall 1 where we look forward to telling you all about our bagging and palletizing news.

And please be confident: Both we and the fair organization have taken all steps to ensure that Khimia 2020 will be a safe and pleasant event for both our visitors and our stand personnel.

Ask us for your Visitor Ticket here