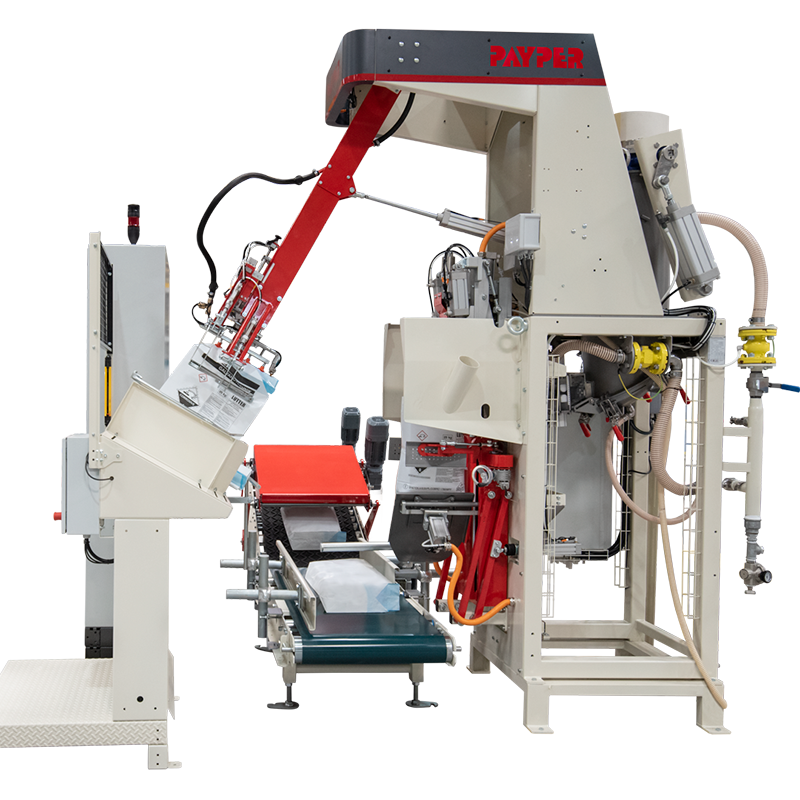

When it comes to bagging and palletizing of human food products the hygiene needs to be optimum. PAYPER has the bagging machinery that complies with the strict regulations in this industry.

Traceability and food safety are major concerns of all stakeholders in the food industry.

The same product may be used in different recipes or formulations and undergo several processes and pass through several companies before arriving to the end consumer.

In order to ensure food safety to your customers, the quality of the product through the whole process has to be maintained impeccable. Therefore the packaging equipment must be designed to avoid contamination, it should allow for easy cleaning, as well as for validation.

These requirements to the design of hygienic machines are our main concern when developing machines for the human food industry. PAYPER has developed a wide range of dosing, weighing and packaging equipment for all types of bag sizes including bulk bags, perfectly adapted to the specific needs of the human food industry.

PAYPER supplies complete packaging line solutions, integrating palletizing and over-packing and each component is perfectly adapted to handle human food in a safe and responsible way.

NEED HELP?

One of our agents will contact you

General Catalogue

DownloadSolutions

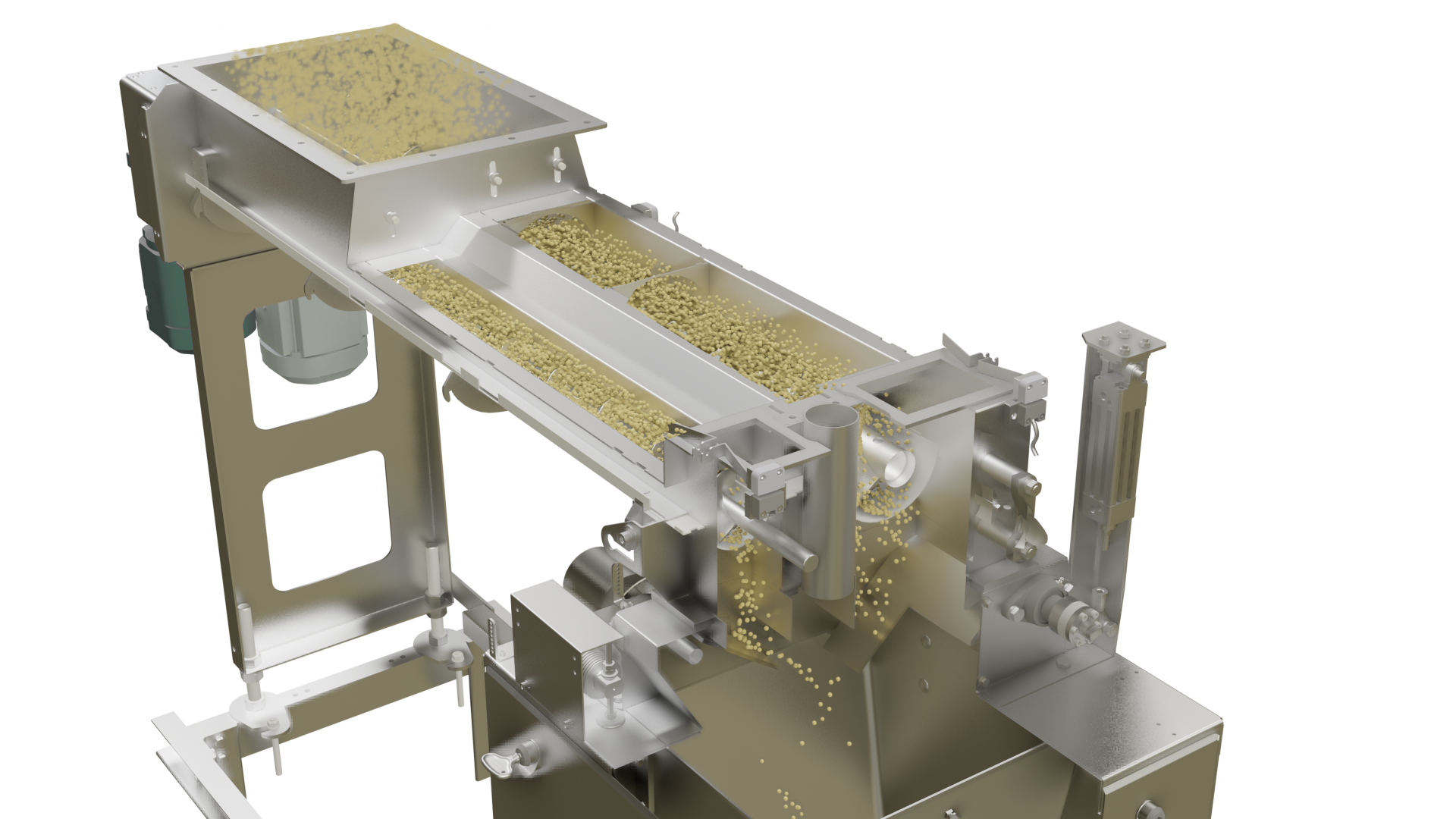

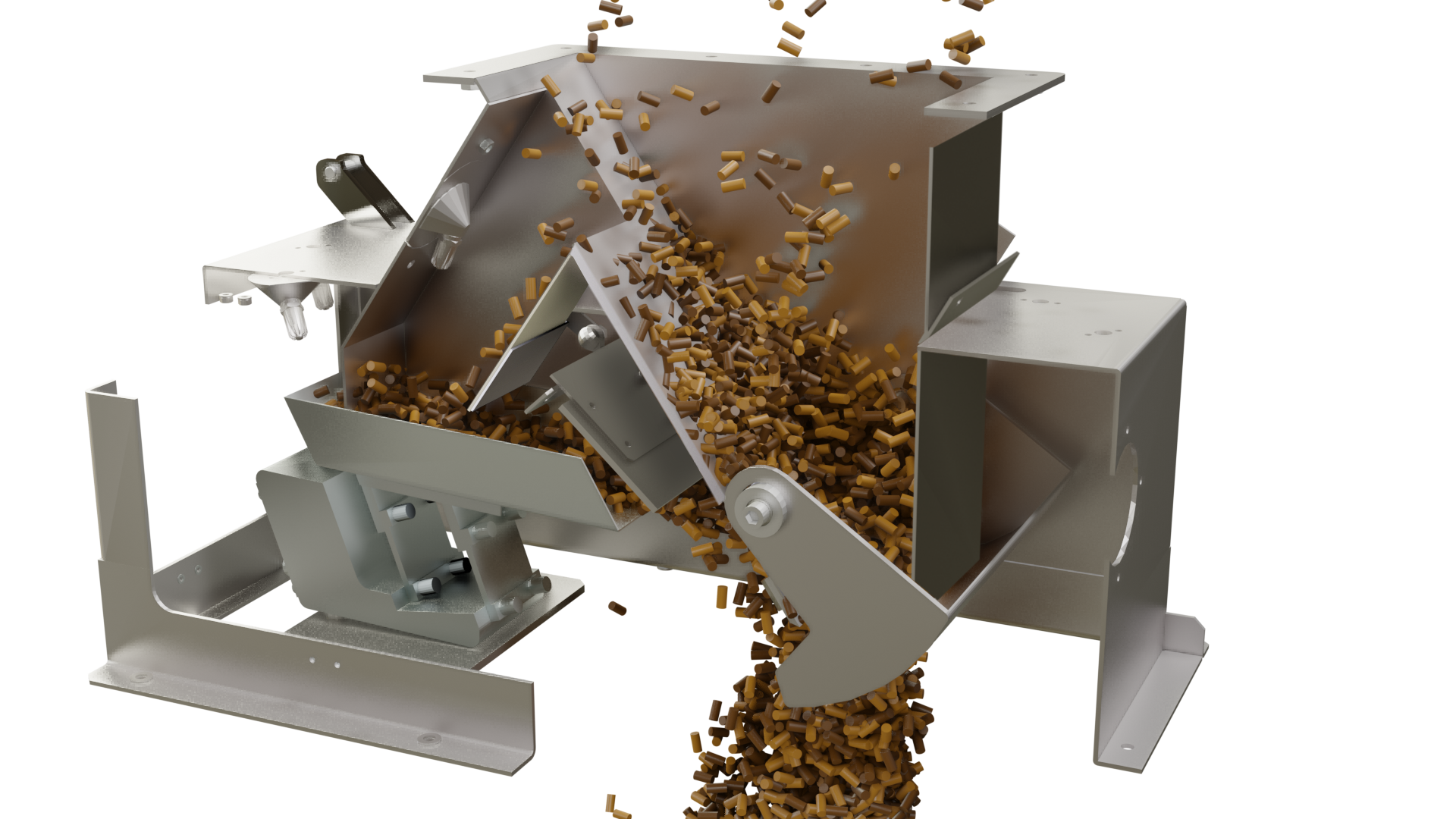

Dosing and weighing

PAYPER offers a comprehensive weighing and dosing solution for all types of dry bulk materials, whether they are free-flowing or not, including powders, flakes, and granulates.

There are two primary principles that govern the weighing and dosing process:

- Gross weight: In this method, the product is directly weighed within the bag. It is typically employed for lower speeds.

- Net weight: With this approach, the product is first weighed in a pan before being released into the bag. This system is generally utilized for higher speeds and great accuracy.

PAYPER ensures that regardless of the nature of the dry bulk goods, they have a suitable weighing and dosing solution to meet the specific requirements of each application.