Bagging

50 years of experience

High-performance bagging machines: accurate, fast and reliable

PAYPER is one of the leading manufacturers of complete bagging lines.

PAYPER has been developing high-performance bagging equipment for 50 years and can satisfy the demands of any required production capacity: from a low to a high degree of automation.

Our wide range of bagging machines enables us to provide solutions to many different industries: Mining, Building, Petrochemical, Chemical and Fertilizer Industries. Further, PAYPER is one of the important suppliers in the sectors of Food for Human Consumption, Animal Feed and Non-Food Crops. We have machinery for all kinds of bags: FFS, Open Mouth, Valve Bags and Big Bags.

NEED HELP?

One of our agents will contact you

General Catalogue

DownloadVIDEO ASSAC U20 - High Speed FFS

watch videoOther solutions

TUBULAR FFS

A Form, Fill and Seal bagging machine is an integrated solution in a compact system. The bag is cut and formed from a continuous tubular reel of LDPE or laminated aluminium reel.

The Tubular FFS bag is an efficient solution for bagging all types of powder or granulates applied in the food industry, such as salt or sugar, etc. It is also used in the petrochemical, fertilizer and building materials industry amongst many other applications.

Every industry has its own peculiarities, and PAYPER offers specific options to adapt to each of them.

We have a specific hygienic design for the food and chemical industries and an anti-corrosion kit for handling corrosive and abrasive products

Our products

-

ASSAC U20 FFS

The ASSAC U20 is a high speed compact bagging machine particularly indicated for petrochemical products. Capacity upto 2.600 bags/h. Can be equipped with an automatic reel exchanger. Possibility of fitting this FFS bagging machine on a movable platform.

watch video -

ASSAC F20

ASSAC F-20 is a high output capacity bagging machine with performances of up to an impressive 2,000 bags/hr. It is designed for easy to handle, free flowing products such as fertilizers, all types of plastic pellets and salt or sugar, etc.

watch video

Valve Bags: Infinite Applications

Valve bags or self-closing bags have an infinite number of applications. Powdery products or even blends of powders and granulates can easily be packed in paper or plastic valve bags with de-aeration systems by means of PAYPER’s unique fluidization technology.

Granulates or any kind of free flowing products can be packed in valve bags by means of the gravity system.

An ultra-sonic valve sealing system guarantees a tight, closed bag. It further ensures efficient protection of the product in the bags and avoids any product leakage.

Our products

-

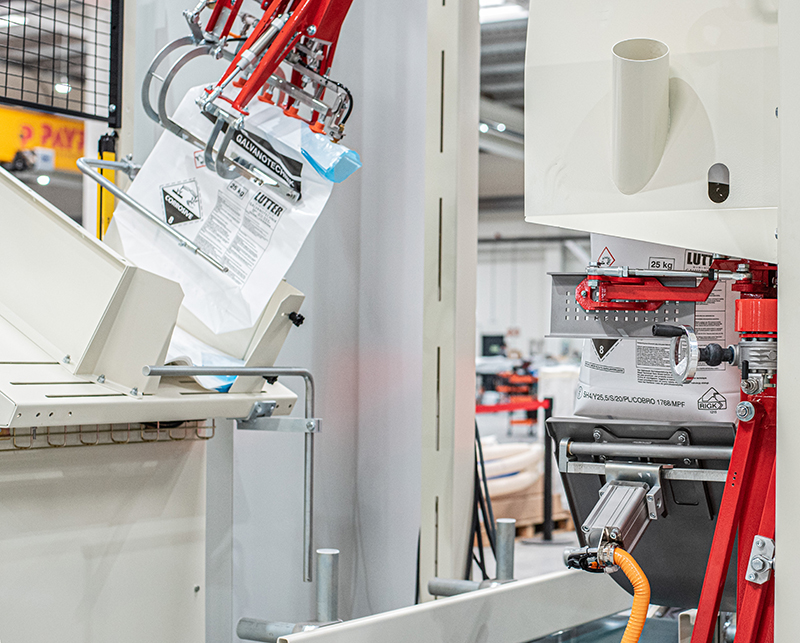

ALL-IN-ONE compact valve bagging and palletizing

The ALL-IN-ONE robot is one of the market's most compact solutions for automatic bagging and palletizing. It can handle all sorts of valve bags: paper, PP or PE.

This robot is particularly suited for bagging of powdery and free flowing products: flour, starch, yeast, milk powder, pre-mixes for bakeries, vitamin correctors, mortar, fertilizer, fine chemicals, PVC, pigments, etc.

The robot handles the whole process: It picks up the empty bag, it presents the bag to the filling spout and it palletizes the filled and closed bag.

- Weight range: from 5 to 50 kg

- Speed: Up to 300 bags/h

watch video -

PFG AIR PACKER

The PFG air packer is designed for bagging powder products, or small granulate or even blends.

It is well adapted to chemicals like PVC and resins. Building materials like mortars, render, adhesive and food products like flour, starch, premixes and the like.

It comprises of a special hygienic design which is very easy to clean.

Several PFG may be placed in line and the speed can be raised up to 2,000 bags/hr.

- Weight range: from 5 to 50 kg

- Speed: 300 up to 500 bags/hr per spout

-

PFG CSV AUTOMATIC BAG PLACER

The fully automatic bag placer CSV is available with different bag magazine capacities. The magazines are automatically adjustable for different bag sizes.

watch video

Open mouth bag

The open mouth bag is a pre-made bag in paper, PE, PP, Aluminium or even combined PE and Paper.

The open mouth bag technology presents good flexibility for all different sizes of bags, which may have to be packed on the same line.

Bags of different materials can be used on the same line, e.g. packing one batch in paper bags and the next in PE bags. Different types of bags may also be used, with or without gussets, block bottom, pinch bottom, etc.

Furthermore, this flexible technology offers the possibility of utilising various de-aeration systems of the product inside the bag, which include vacuuming the bag before closing, nitrogen injection, and other systems.

The wide range of bagging machines for open mouth bags starts with the semi-automatic line and ends up with the fully automatic version with capacity of up to 1,800 bags/hour.

Bag closing can be achieved by many various methods dependent on bag material, which include heat sealing, sewing (with or without tape) or even folded and glued with pre-glued bag tops.

Our products

-

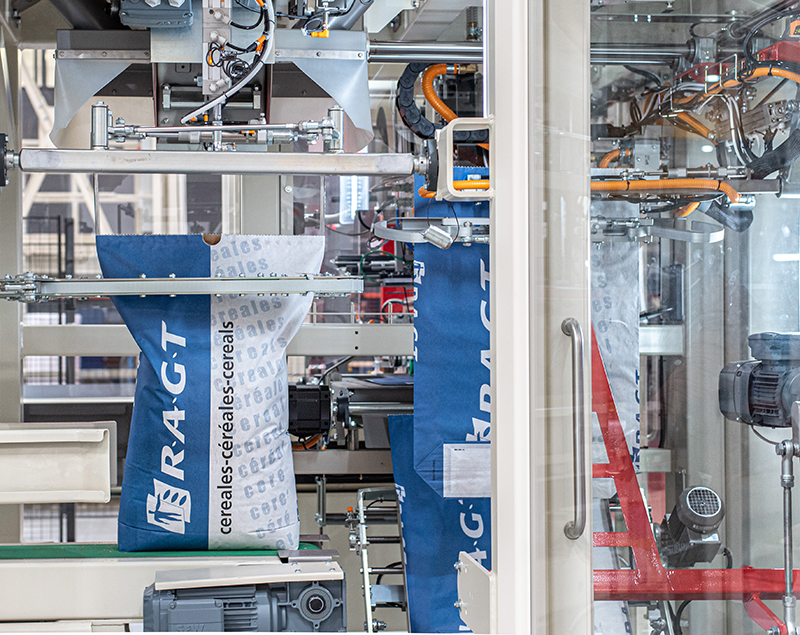

CSA Open Mouth Bagger

Easy change of bag size and compatible with a long list of bag materials.

There are different models available, offering speeds between 400 and 1,800 bags/hour

They are indicated for dry bulk goods from powder to granules.

Easy access for quick maintenance.

watch video -

CSA - Custom-made Bagging

The CSA open-mouth baggers are modular to perfectly adapt the bagging process to your product and production.

Examples of modules:

- Probe with double function: emptying the bag and/or fill it with inert gas

- Special configurations for bagging corrosive, abrasive or explosive products.

- Thorough Cleaning to prevent cross-contamination

- Automatic alignment of the bag for perfect sealing

watch video

BIG BAG or FIBC and OCTABIN filling station

Our comprehensive range of filling stations is designed to cater to various bulk materials transportation and storage needs. These filling systems are perfectly suited for a wide selection of substances, including chemicals, plastic pellets, fertilizers, seeds, building materials, and food products.

At PAYPER, we understand the diverse requirements of our customers when it comes to handling Big Bags. That's why we offer filling stations that are specifically tailored to handle Big Bags with 1, 2, or 4 straps. Depending on your preferences, these Big Bags can be easily managed with or without the use of a pallet.

For maximum efficiency, our filling stations allow for the stacking of two Big Bags on top of each other, optimizing storage space and streamlining operations. Our dedicated filling stations fill FIBC (Flexible Intermediate Bulk Container) bags and Octabins, with a capacity from 500 to 2,000 kg.

When it comes to our filling systems, various configurations are available to meet your specific requirements. These configurations take into account factors such as the nature of the product being handled, the type of Big Bag or Octabin in use, and the desired capacity.

Choose PAYPER for reliable and flexible filling solutions that cater to your unique needs.

Our products

-

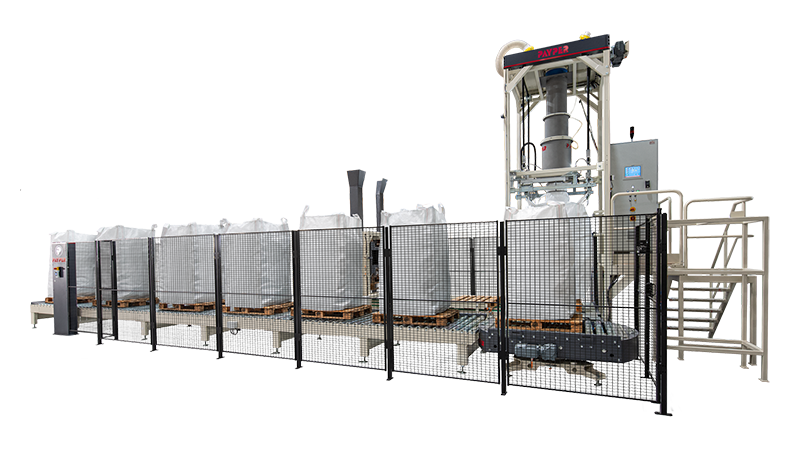

GROSS WEIGHT FILLING MACHINES

This automatic filling system efficiently handles up to 35 Bulk Bags per hour, accommodating various product characteristics. Its user-friendly and ergonomic design, along with its adaptable configuration, provides customized solutions for FIBC and OCTABIN filling. Additionally, a semi-automatic variant of the Jumbo Bag filling machine is available, enabling a throughput of 15 Big Bag/hr, ensuring suitability for diverse client requirements

-

AUTOMATIC NET WEIGHT FILLING SYSTEM

The high-output capacity of the automatic net weight filling machines make them ideal for different applications within bulk bag filling. With the ability to handle up to 100 BB/hr, these versatile filling stations ensure efficient operations, for many different products. The precise weighing capabilities of these Big Bag filling stations and their durable design allow for long-lasting performance, even in harsh environments like fertilizer plants.

Do you need a custom solution?

© PAYPER, S.A. 2017. All rights reserved.

Pol. Ind. “Vinyes del Mig”, parc. 12-14 | 25220 Bell-lloc d’Urgell | Lleida | SPAIN · (+34) 973 216 040

Web Project developed by ACTIUM Digital