Happy Holidays and all the best for the New Year 2025!

As 2024 comes to a close, we want to extend our warmest wishes to all our employees, customers and partners. May this holiday season bring you joy, peace, and happiness. We look forward to continuing our journey together in 2025.

Happy Holidays and a Joyous New Year!

Related images

PAYPER has inaugurated new facilities in India

PAYPER has inaugurated the new facilities of its PAYPER INDIA branch: offices in the business centre of Mumbai, reinforcing PAYPER’s position as a trusted partner for bulk bagging lines, and a new manufacturing centre of over 4000 m² in PUNE´s Technology Park.

This expansion places us in the perfect position to meet the growing demand for advanced and reliable bagging solutions, enhancing our customer service for all clients in the region.

Related images

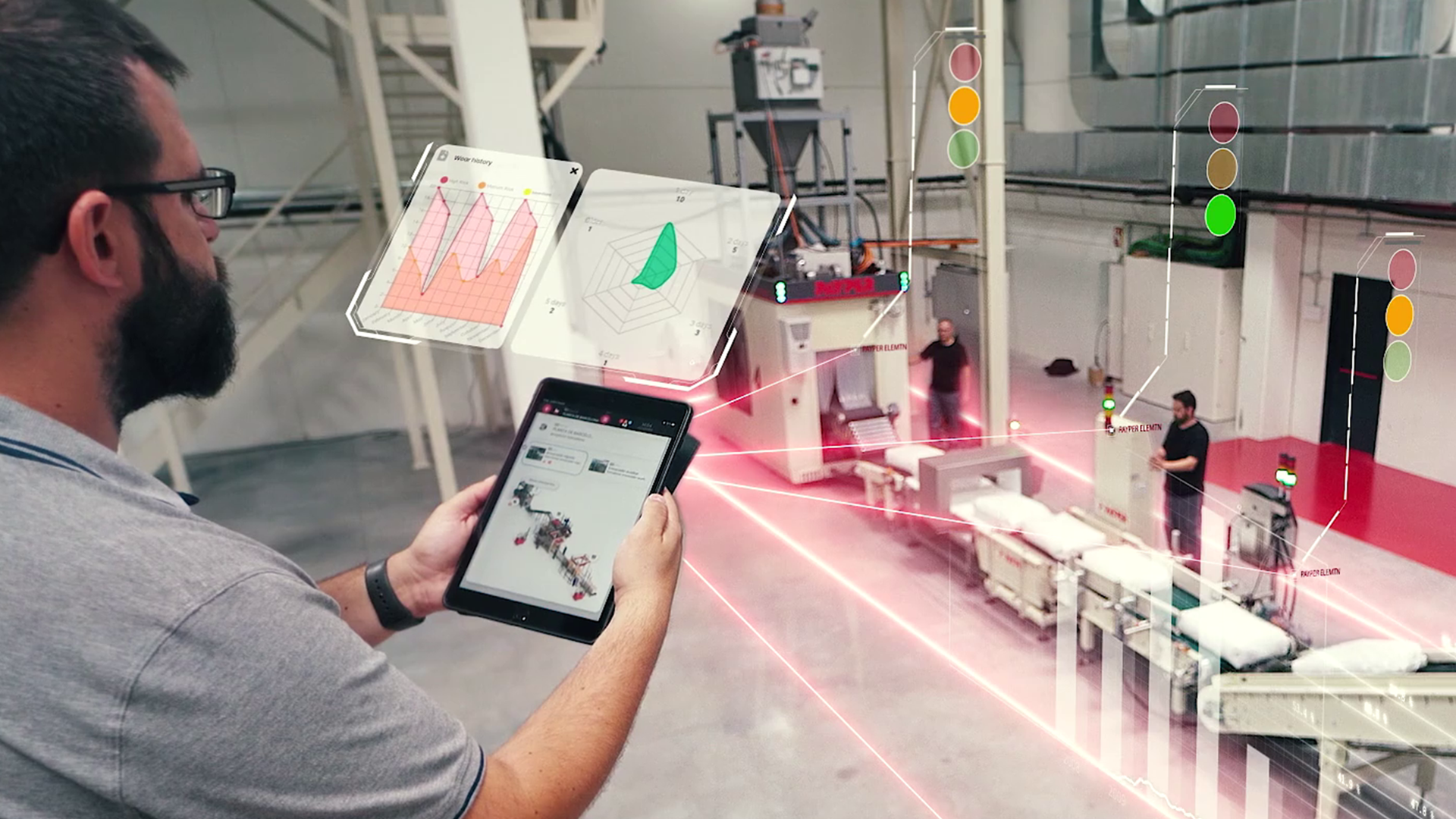

PAYPER focuses on digitalization, accuracy and performance.

PAYPER focuses on digitalization, accuracy and performance.

Interpack, Düsseldorf, Germany. May 4-10, 2023 – PAYPER, one of the leaders in the bagging industry, is launching Pulsar, an all-in-one digital solution for advanced bagging management and service, at Interpack (Hall 12, Booth C06). MSX, the new weight controller, and the FFS bagger from the ASSAC series will also play a prominent role in the show.

PAYPER stands for accuracy, control and performance.

Accuracy.

Weighing has been at the centre of interest in PAYPER’s R&D&I department ever since the first weighing device was designed in 1973. In line with the ongoing commitment to weighing accuracy, PAYPER will present MSX: a new dynamic weight controller. It ensures maximum accuracy at high bagging speeds, being one of the most accurate weighing systems in the bagging industry. Accredited by official metrology institutions, it is specifically designed for the bagging of all types of solid products: granules, flakes and fine powders.

Control.

Pulsar ensures full control of the production processes with a single click. This new cloud-based software solution enables bulk good producers to digitalize their bagging lines taking their production to the next level.

At PACK EXPO International in Chicago in 2022 PAYPER introduced the Pulsar-S, to enhance customers’ after-sales-service experience. We are now introducing Pulsar M at the main meeting point for the packaging industry worldwide, Interpack 2023.

This all-in-one digital solution allows advanced management of production and service:

Pulsar S: Smart Customer Service and Maintenance.

Make the most of your production line with Pulsar S. The different modules allow plant managers, maintenance managers and operators to work together to increase the lifetime and effectiveness of the bagging line machinery. Among other actions, it is possible to perform:

- Predictive Maintenance: risk management, task scheduling and tutorials to reduce maintenance costs and machinery downtime.

- Quick spare parts management: orders, stock and deliveries.

- Easier Customer Service communication: Omnichannel support.

- Remote training and technical support: using augmented reality.

- Data-driven decisions: real-time KPIs and analytics.

Pulsar M: Future-proof production management

Pulsar M is a cloud-based software solution for the collection, visualization and analysis of data from complete bagging lines: from dosing to warehouse management. Among other functions, it is possible to access:

- Overall Equipment Efficiency (OEE) measurement.

- Alarm management: Step-by-step indications.

- Traceability: batch management.

- Monitoring: The status of every machine in the line can be monitored from any one of them.

Move towards Industry 4.0 with PAYPER!

Performance.

PAYPER designs and manufactures high-performance bagging lines for industry leaders: Turnkey projects including dosing, weighing, bagging, palletizing and overwrapping.

- Dosing and weighing: Wide range of dosing systems that adapt to the size, shape and fluidity of the product: gross or net weight, free-flowing or not, powdery, flakes or granulates.

- Bagging: High-performance automatic bagging machines for open-mouth bags, valve bags and FFS-tubular bags. Also, filling stations for Big Bag production lines.

- Palletizing: A wide range of robot and conventional palletizers for perfect pallet stability.

- Overwrapping: End-of-line solutions for ideal finishing and protection such as wrapping machines and stretch hood machines.

PAYPER will be showcasing an FFS bagging machine from the ASSAC series at the stand. This bagging system forms, fills and seals bags from a continuous tubular reel of plastic. An efficient solution for bagging all types of bulk solids applied in the food, petrochemical, fertilizer and building industries. The ASSAC FFS bagging machine stands out for its compact and heavy-duty design with easy access for cleaning and maintenance. Among the available options are: hygienic design for the food and chemical industries and an anti-corrosion configuration for handling corrosive and abrasive products. Do not miss the opportunity to see first-hand one of the fastest bagging machines on the market with performances of up to 2,600 bags/hour.

Find out more about PAYPER’s product range and the new digital solution, Pulsar, by booking a meeting in advance. Our specialists will be happy to welcome you at our stand C06 in Hall 12 at Interpack from May 4 to 10, 2023.

50th anniversary

PAYPER is celebrating an important milestone in its history in 2023, its 50th anniversary.

"We are very proud of what we have achieved since we designed our first weighing system for the fertilizer industry in 1973. Today, we are recognized worldwide as one of the market leaders in packaging for bulk solids. This has only been possible as a result of the close collaboration with our worldwide team, our long-term partners and our customers which has taken us to where we are today."

Josep Mª Godia, Managing Director at PAYPER.

Related images

Visit us at ProPak Asia

From 20 to 23 of October, PAYPER Asia Pacific will be at ProPak Asia in Bangkok.

We have taken all precautions to make it a safe and pleasant event for our guests as well as for our employees. It is with much illusion that we attend this exhibition and hope that many of our business-contacts will come and visit our booth to discuss the newest developments within bagging and palletizing.

If you wish, you can pre-book your visit and ask us for your invitation here.

We look forward to seeing you at ProPak Asia!

Related images

PAYPER opens the 8th subsidiary, PAYPER RUSSIA CIS

PAYPER has just opened its new subsidiary in Russia, following our strategy to be close to our clients. To us, proximity makes communication easier and service faster and more efficient – always thinking of our clients.

Mr Alexander Semernikov has been appointed Field Sales Manager in PAYPER RUSSIA CIS and he will coordinate the daily work as regards to sales and service in the Russian market.

Our agent in Russia during many years, SWEMA, will continue their excellent work in the market and will now be in direct contact with Alexander Semernikov.

The yearly Russian Sugar Seminar, “Technolog Club 2020” has been organized as a webinar on this occasion. PAYPER participated in the event again this year - watch the introduction of Alexander’s talk on “FFS Bagging Technology for Sugar” here.

Related images

25th-anniversary PAYPER-TOMADONI

We are celebrating! The cooperation between PAYPER and Tomadoni in the argentine market is now 25 years old.

The collaboration between Industrias Tomadoni and PAYPER started in January 1995 in order to open the local market for bagging equipment. Since then we have been very successful in developing our common project in Argentina, where ITSA has been marketing PAYPER’s solutions for dosing, weighing, bagging and palletizing.