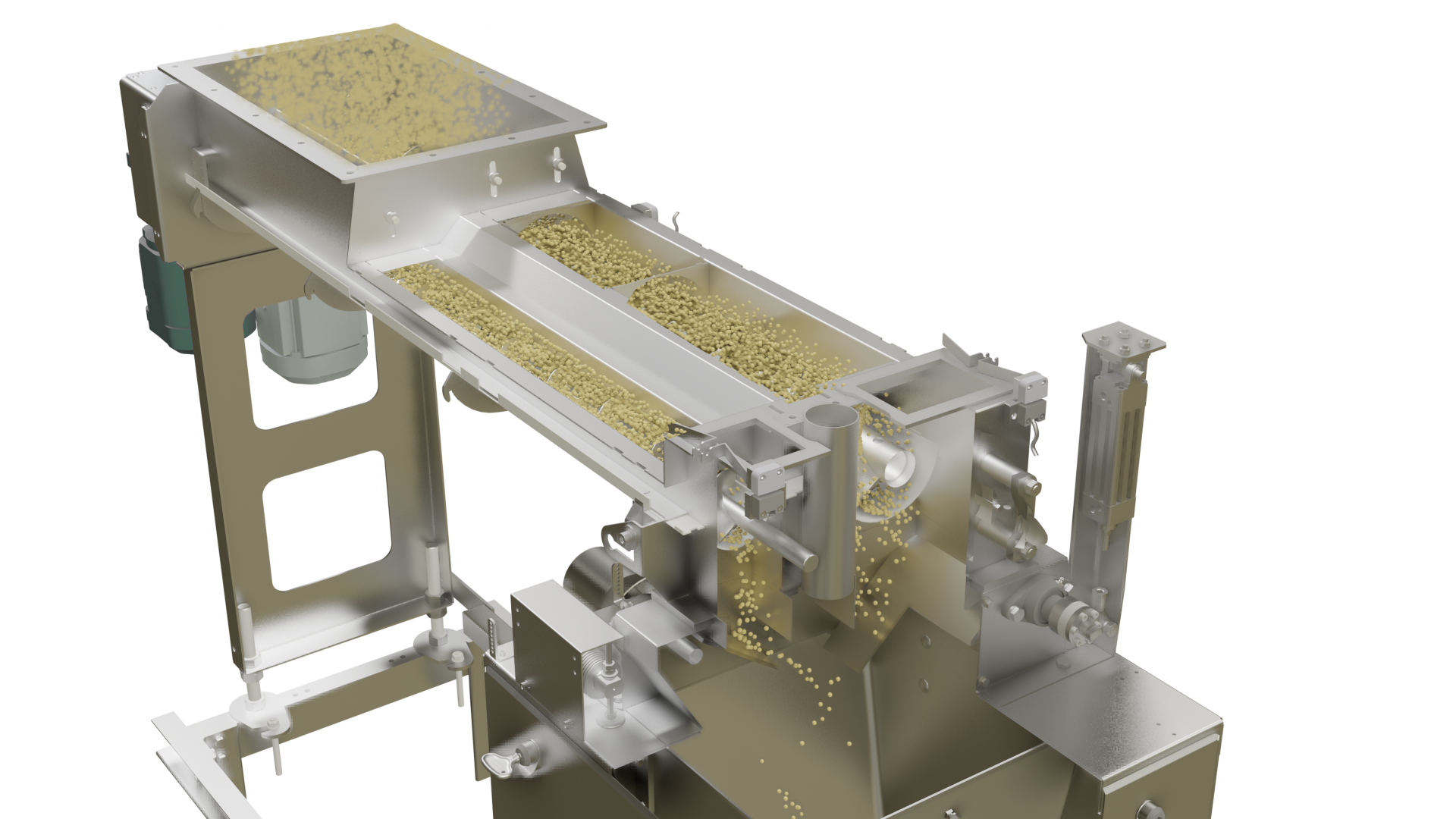

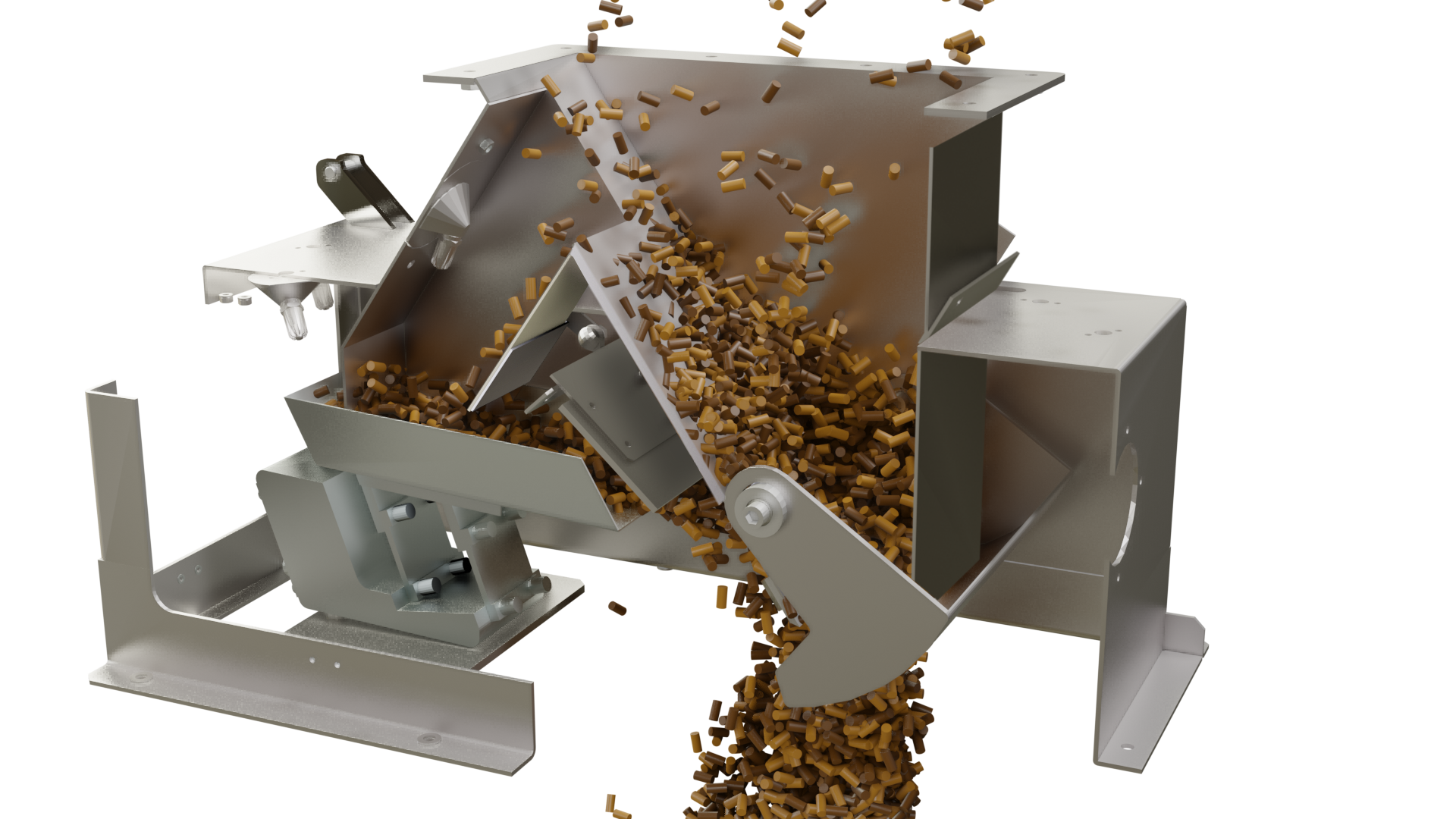

PAYPER offers a comprehensive weighing and dosing solution for all types of dry bulk materials, whether they are free-flowing or not, including powders, flakes, and granulates.

There are two primary principles that govern the weighing and dosing process:

- Gross weight: In this method, the product is directly weighed within the bag. It is typically employed for lower speeds.

- Net weight: With this approach, the product is first weighed in a pan before being released into the bag. This system is generally utilized for higher speeds and great accuracy.

PAYPER ensures that regardless of the nature of the dry bulk goods, they have a suitable weighing and dosing solution to meet the specific requirements of each application.

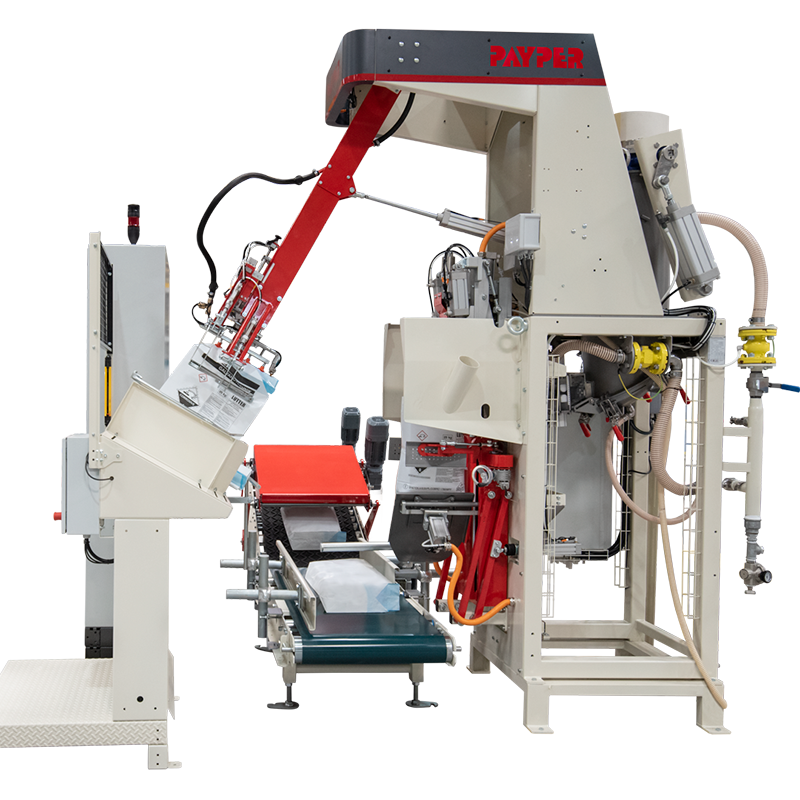

PAYPER is a renowned manufacturer of complete bagging lines. With over 50 years of experience, we have been providing bagging solutions to clients across various industries. Our extensive range of bagging machines allows us to offer tailored solutions to diverse sectors such as Mining, Building, Petrochemical, Chemical, Fertilizer, Food for Human Consumption, Animal Feed, and Non-Food Crops. We cater to all types of bags, including FFS, Open Mouth, Valve Bags, and Big Bags.

When it comes to establishing long-term business relationships, quality and reliability are our top priorities. We take pride in having successfully completed over 4,000 projects for clients in more than 75 countries worldwide.

Our bagging machines are designed for high performance, offering accuracy, speed, and reliability.

Once the bags are filled, sealed, and quality checked, they need to be palletized before they can be transported to their destination. Ensuring proper palletization is crucial for safe long-distance transportation. PAYPER provides a range of palletizers to cater to diverse requirements.

Irrespective of the type of bag that needs to be palletized, PAYPER has the ideal solution to achieve high-quality palletization. Palletizers with a high infeed level are suitable for bagging operations that require fast speeds. When it comes to medium and high speeds, the conventional high-level infeed palletizer (HLP) is well-suited for Valve Bags or FFS bags. PAYPER also features a high-level infeed palletizer with a gripper head (HLG).

For Open Mouth bags, the low-level infeed palletizer (LLG) with a gripper head is excellent, allowing for overlapping at medium speed. On the other hand, the low-level infeed palletizer with row-push function (LLP) is specifically designed for valve bags and FFS bags.

When multiline palletizing is required, the robotic solution proves to be perfect. It efficiently combines the tasks of positioning the empty pallet, inserting the slip sheet, and depositing the bags.

To complete the bagging and palletizing process, we employ automatic quality control devices and end-of-line equipment. These include check weighers, metal detectors, and bag leakage control devices, which ensure that the contents of the bags are untainted and that the bags are of the correct weight.

Once the bagging and palletizing process is complete, the last step before storage and transportation is protecting your pallets. We utilize an efficient End-of-Line Stretch Hood system for this purpose. This method guarantees optimal pallet stability during transport, while also efficiently shielding the bags from humidity and dust, ensuring their protection.